In conveyor technology, the systems are often expanded with additional components to ensure a smooth process. These additional components increase the functionality and performance of the transport systems. These include various elements such as labellers, scanners, camera systems, weighing devices, workpiece carriers in a wide variety of designs, as well as other devices and individual systems. Conveyor systems with supplementary components support the smooth running, monitoring and flexible handling of goods on the conveyor systems and are crucial for automation, monitoring and increasing efficiency within a conveyor system.

Supplementary components for transfer systems

Advantages of the supplementary components from TEGEL-TECHNIK

Our supplementary components are perfectly matched to the respective product and the specific conveyor technology. By integrating the electrical components into the control system of the conveyor system, we avoid additional interfaces. Comprehensive delivery from a single source not only ensures smooth functionality, but also prevents additional costs from planning to installation of the transfer system.

As a specialist and experienced manufacturer of conveyor technology, we at TEGEL-TECHNIK supply comprehensive systems and customised components such as roller conveyors, chain conveyors, curved conveyors and pallet conveyor technology. Our broad vertical integration goes hand in hand with an extensive range of products and services, a high degree of flexibility and modular solutions. We draw on many years of experience since our foundation in 1982 as a company for conveyor technology and transport systems.

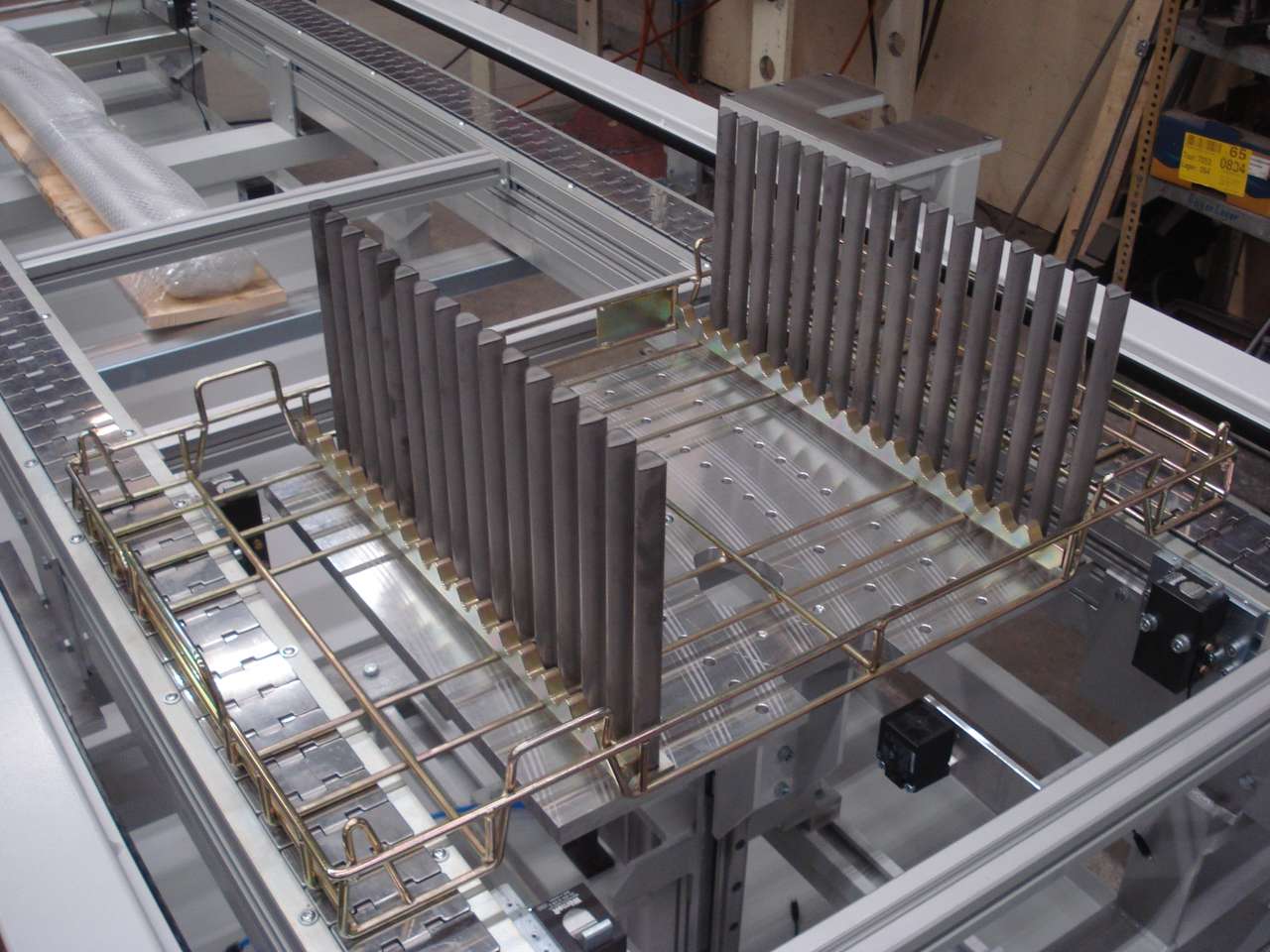

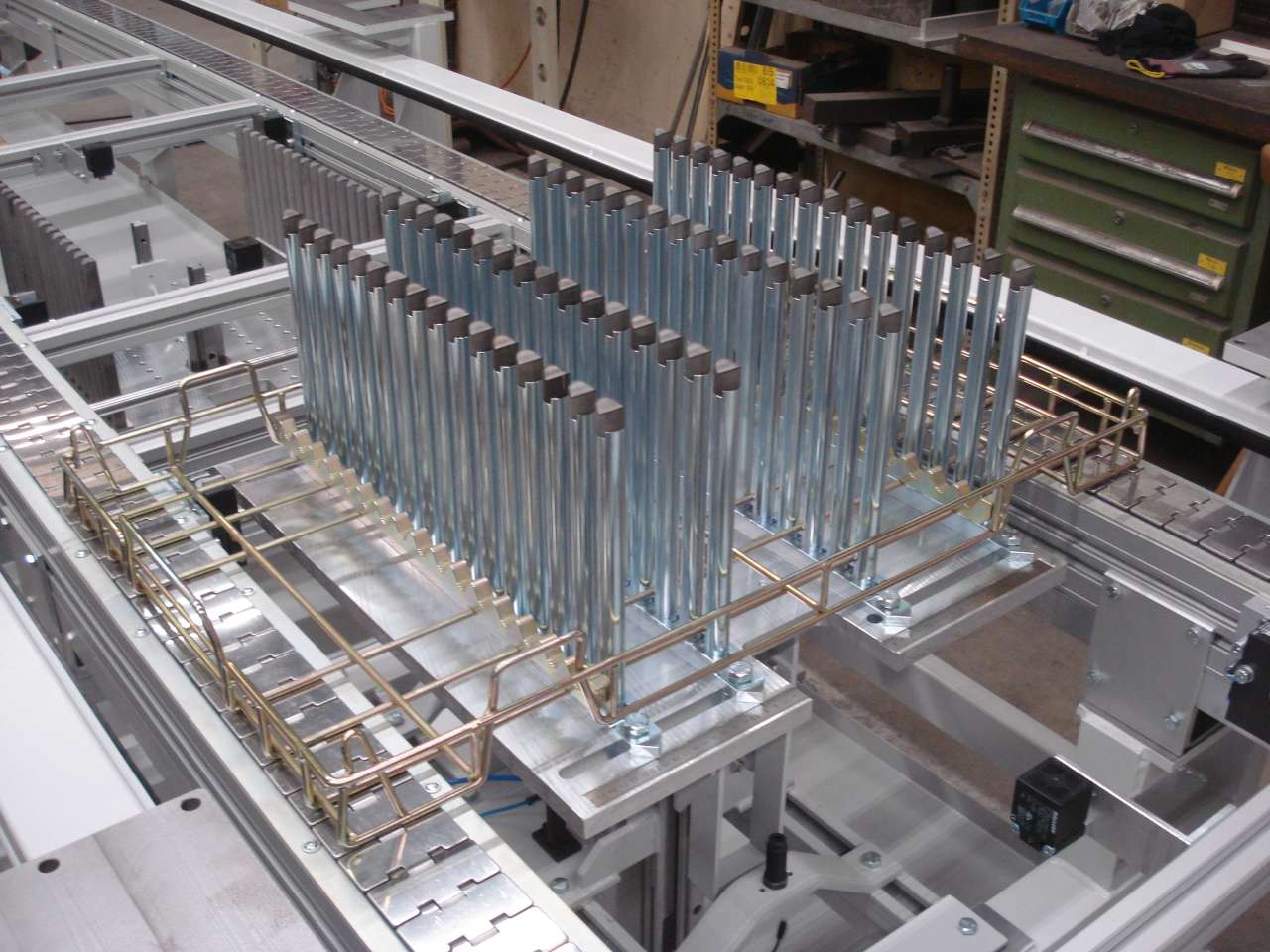

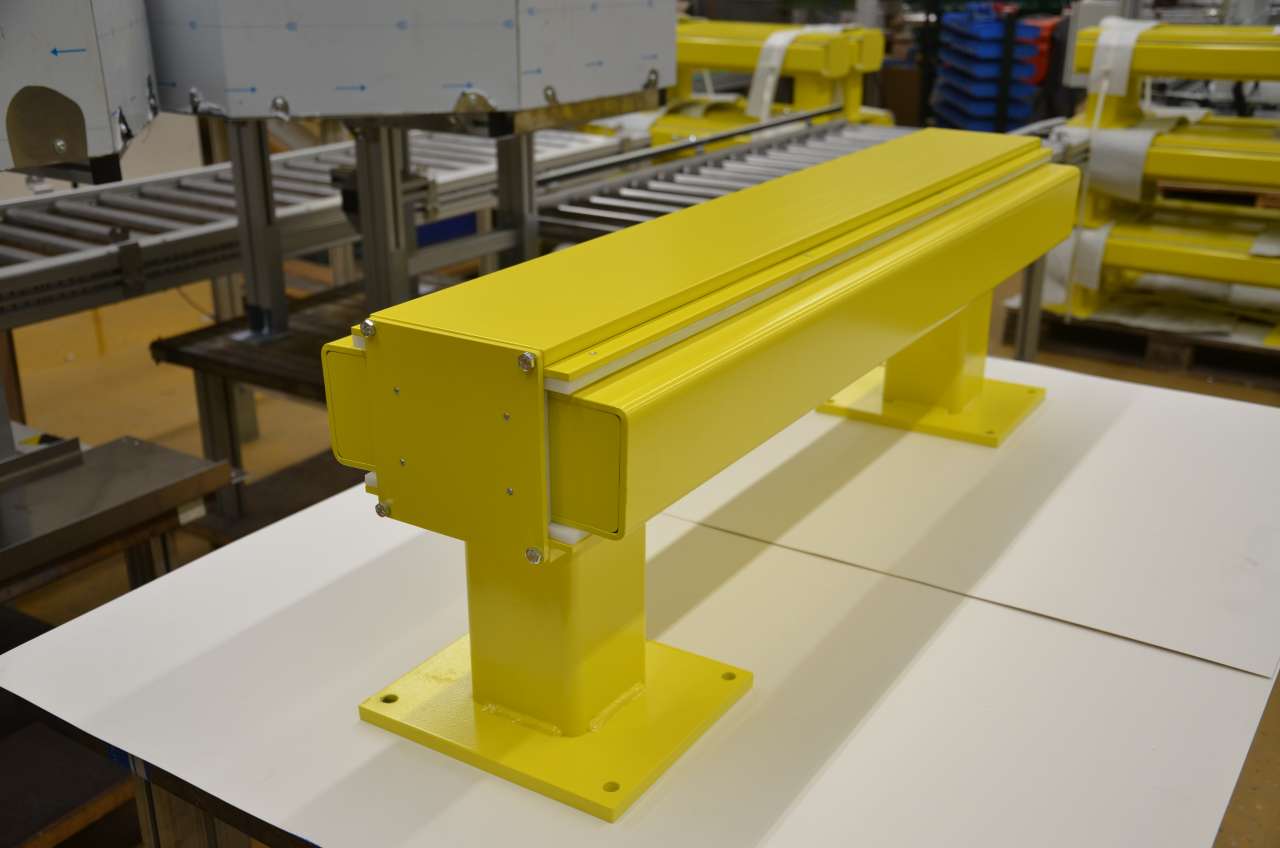

Supplementary component workpiece carrier

Workpiece carriers are special devices or platforms that are used to transport components safely and quickly. This type of conveyor medium often enables the transport of irregularly shaped products on the transport systems. In automated production lines, workpiece carriers play a decisive role in efficient and flexible production. Here, the workpieces often have to be fed to a processing machine in a specific position and orientation. Workpiece carriers and workpiece carrier transport systems are designed to fulfil the specific requirements of the respective production process. Workpiece carriers can be firmly connected to the conveyor line or loosely supported.

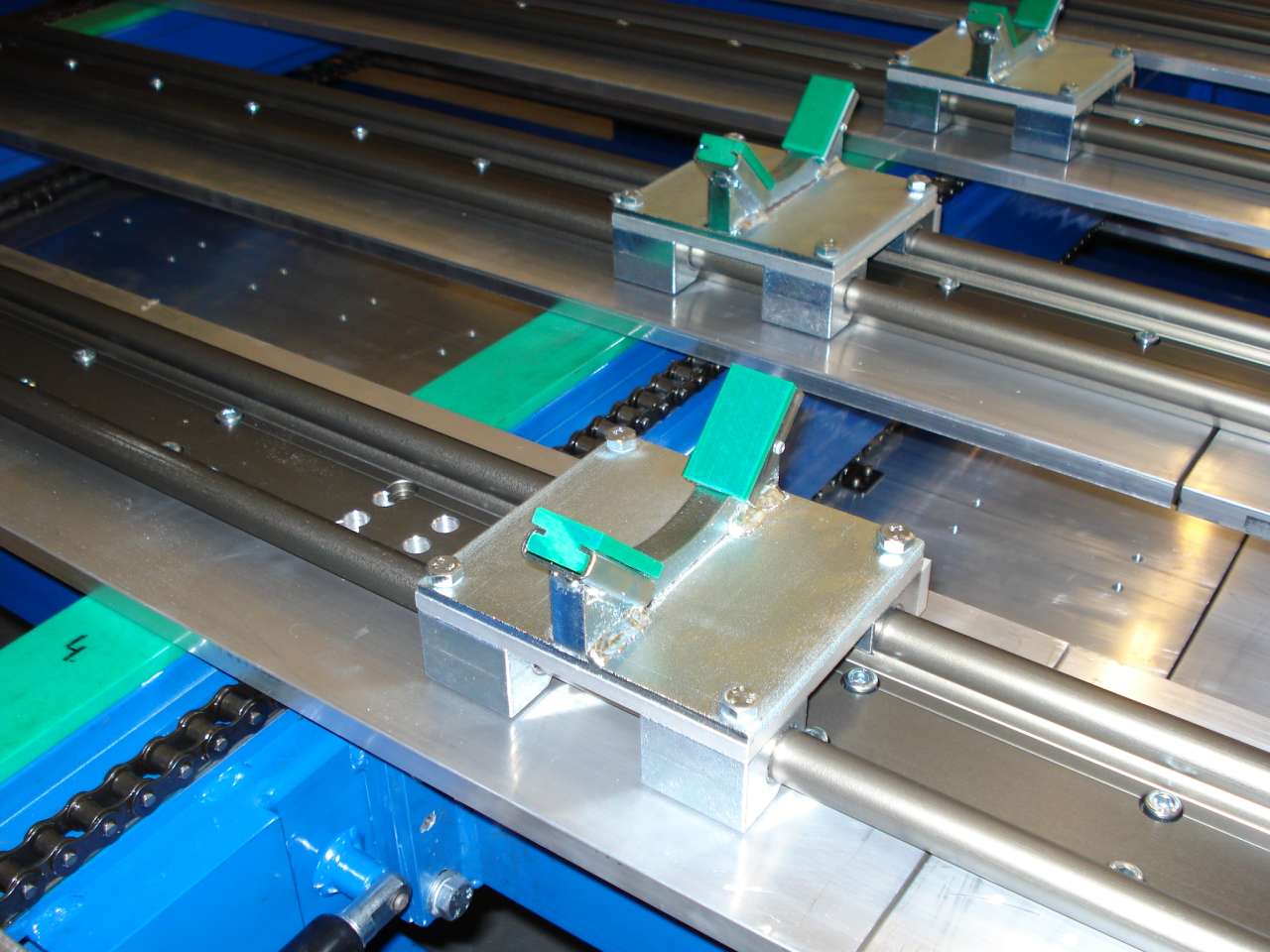

Depending on the characteristics of the products and goods to be transported, workpiece carriers can have different shapes and sizes. Workpiece carrier transport systems can contain specific storage elements, compartments, poka-yoke elements, holders or other constructions to securely fix the workpieces on the transfer system. Workpiece carriers are often designed so that they can be stopped at different stations in a production line and, if necessary, positioned via indexing devices in order to carry out different processing steps within the system.

The use of workpiece carriers contributes to efficiency, precision and safety in production and manufacturing, especially in automated environments where accurate positioning and handling of workpieces on the transfer system is crucial.

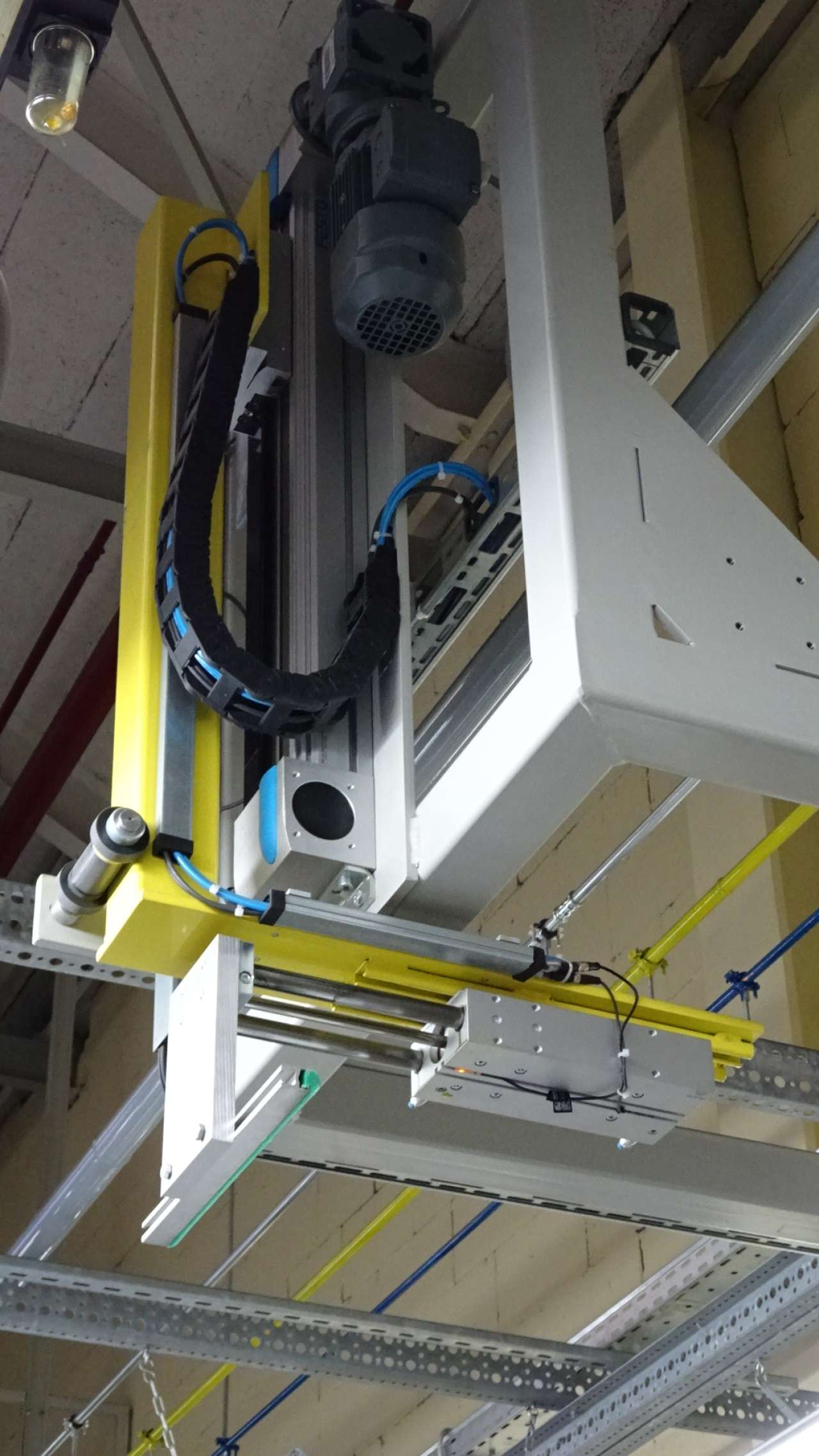

Weighing equipment for transfer systems

Conveyor systems can be expanded with additional weighing equipment. Weighing sensors or weighing platforms are usually installed under the conveyor element for this purpose. The weighing devices are used to control and check the filling or removal processes in the system. They can also protect downstream vertical conveyors from overloading the transport solution.

Complete workpiece carrier transport systems and custom-fit workpiece carriers offer a high level of operational reliability for processes in production and automated manufacturing.

Gallery of our application examples

Have we aroused your interest?

Enquire now for a customised conveyor solution

Phone

+49 7322 9611–0