Accumulating roller chain conveyors are used in conveyor technology to transport goods or materials in work processes, stop them and move them on in the desired sequence. The name accumulating roller chain conveyor is derived from its ability to accumulate goods at certain points while the chain rolls over the rollers installed in it under the conveyed goods. The product-carrying roller runs freely and has no contact with the supporting structure. If the transported goods are stopped while the chain is running, the idler can "turn backwards" and therefore does not damage any goods. During the stops, for example, machining, inspections or other processes can be carried out.

Accumulating roller chain conveyor

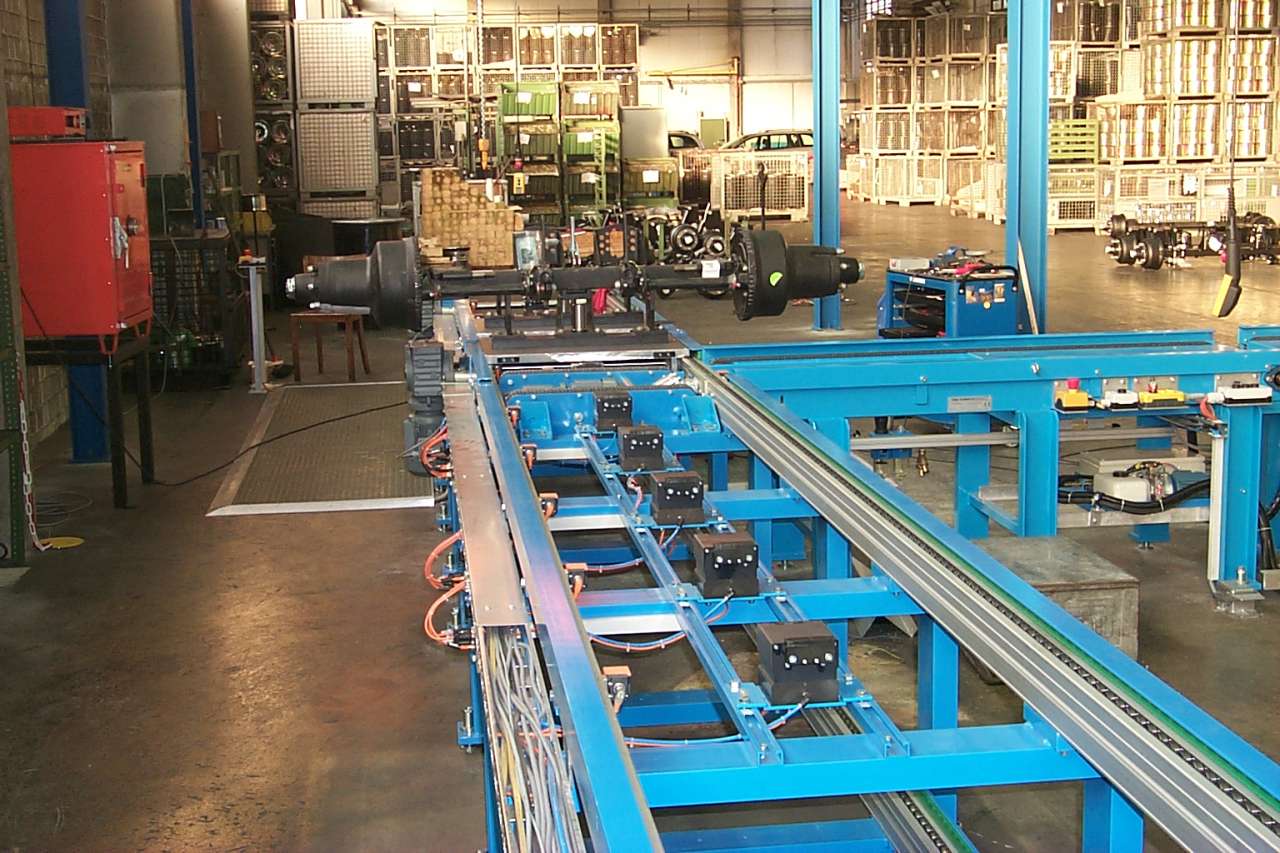

Conveyor systems with this technology are characterised by a low support as well as low back pressure and gentle transport of the conveyed goods. They are ideal for transporting workpiece carriers, e.g. lorry axles, axle guides, engines, camshafts, dishwasher doors, cylinder heads, door frames, etc. in mechanical engineering.

In addition to accumulating roller chain conveyors, we also offer other types of chain conveyors such as carrier chain conveyors, modular belt conveyor, apron conveyors and slat-band chain conveyors. You can find a selection of our realised projects here.

Advantages of accumulating roller chain conveyors from TEGEL-TECHNIK

Broad range of applications: Our accumulating chain conveyors in a compact design are used in various industries and can be easily combined with other automation systems such as robotics and control systems.

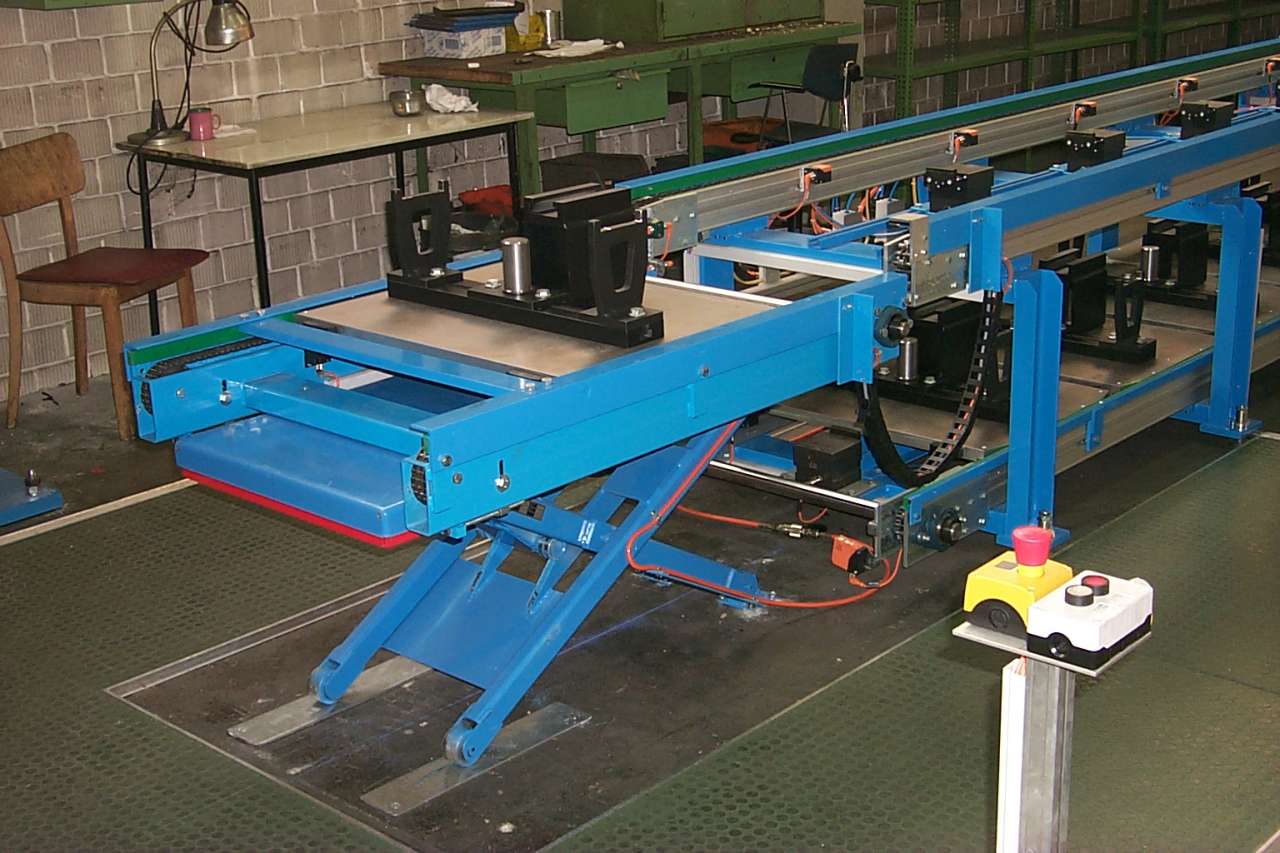

Customisation and flexibility: Our chain conveyors with accumulating rollers are adapted to customer requirements depending on the desired conveying speed and size of the transported goods. The conveyors with a modular design can be supplemented with various additional elements such as stoppers or indexing stations on request.

Rugged and reliable: Our accumulating roller chain conveyors are characterised by a high payload and robust design. This makes them a durable and safe conveyor system for heavy loads.

Efficiency and economy: The design of our accumulating roller chain conveyors is largely maintenance-free. Few maintenance points are easily accessible, which enables fast and cost-effective maintenance. The rolling discharge is not only characterised by its gentle handling, but also significantly reduces the accumulation pressure that is common with abrasive transport systems.

Everything from a single source: We offer a high level of vertical integration with an extensive range of mechanical, electrical and software services. As a company in the field of conveyor technology, we have been drawing on our valuable experience since 1982.

Design and functionality of accumulating roller chain conveyors

Accumulating roller chain conveyors are a special type of chain conveyor characterised by the eponymous accumulating roller chains. Conveyor technology with an accumulation roller chain is able to transport conveyed goods but can also hold them back if required. This is achieved by temporarily fixing the transported goods;

Individual goods can be stopped at any point while the chain continues to run thanks to idlers integrated into the chain. This makes it possible to stop a continuous material flow at certain points in order to carry out specific actions or processing on the transported goods. This type of conveyor system offers more flexibility and control in manufacturing and production processes. Chain conveyors with accumulation rollers are often integrated into automated systems. The control of the rollers, the timing of the accumulation zones and other parameters can be controlled automatically.

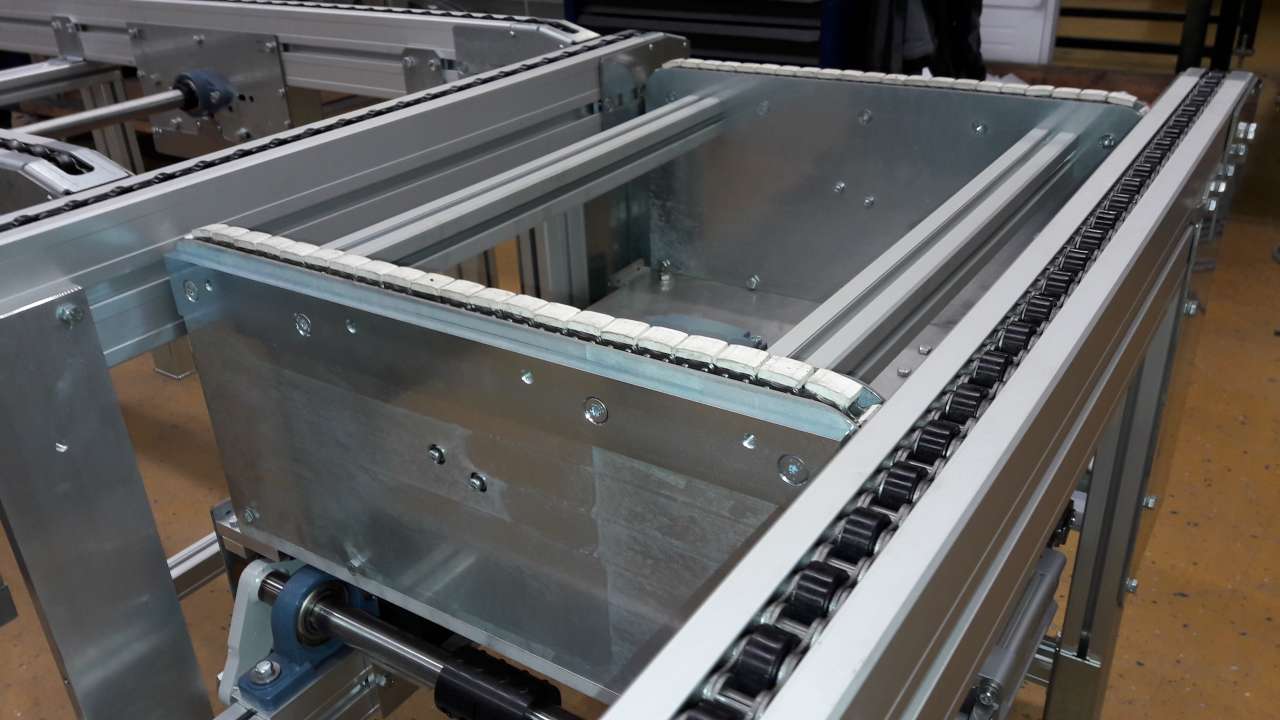

Accumulating roller chain conveyors use special chains that are equipped with additional rollers. These rollers are used to carry the goods or materials or, in the case of accumulation function, to roll under them. The dimensions of the accumulation roller chains are selected individually to suit the transported goods or the specific application. For example, rollers made of steel, plastic or maintenance-free chains can be used.

Thanks to the free space between the conveyor lines, the goods to be transported are accessible from below and there is sufficient space between the lines for the installation of stoppers, fixing units and processing stations.

Chain conveyor with accumulation rollers in use

Chain conveyors with accumulation rollers are used wherever precise control of the material flow is crucial. They are particularly common in industrial processes, especially where goods need to be accumulated, separated and forwarded in a controlled manner.

Accumulating roller chain conveyors are focussed on processes in production and assembly. They form the basic element for the construction of transfer lines in the load area. In this way, several workstations and processing steps can be flexibly linked together. The chain conveyors with accumulation rollers enable the controlled movement of components and products between the various assembly stations without accumulation pressure.

Gallery of our application examples

Have we aroused your interest?

Enquire now for a customised conveyor solution

Phone

+49 7322 9611–0