Teleskopgabel für Roboterzelle

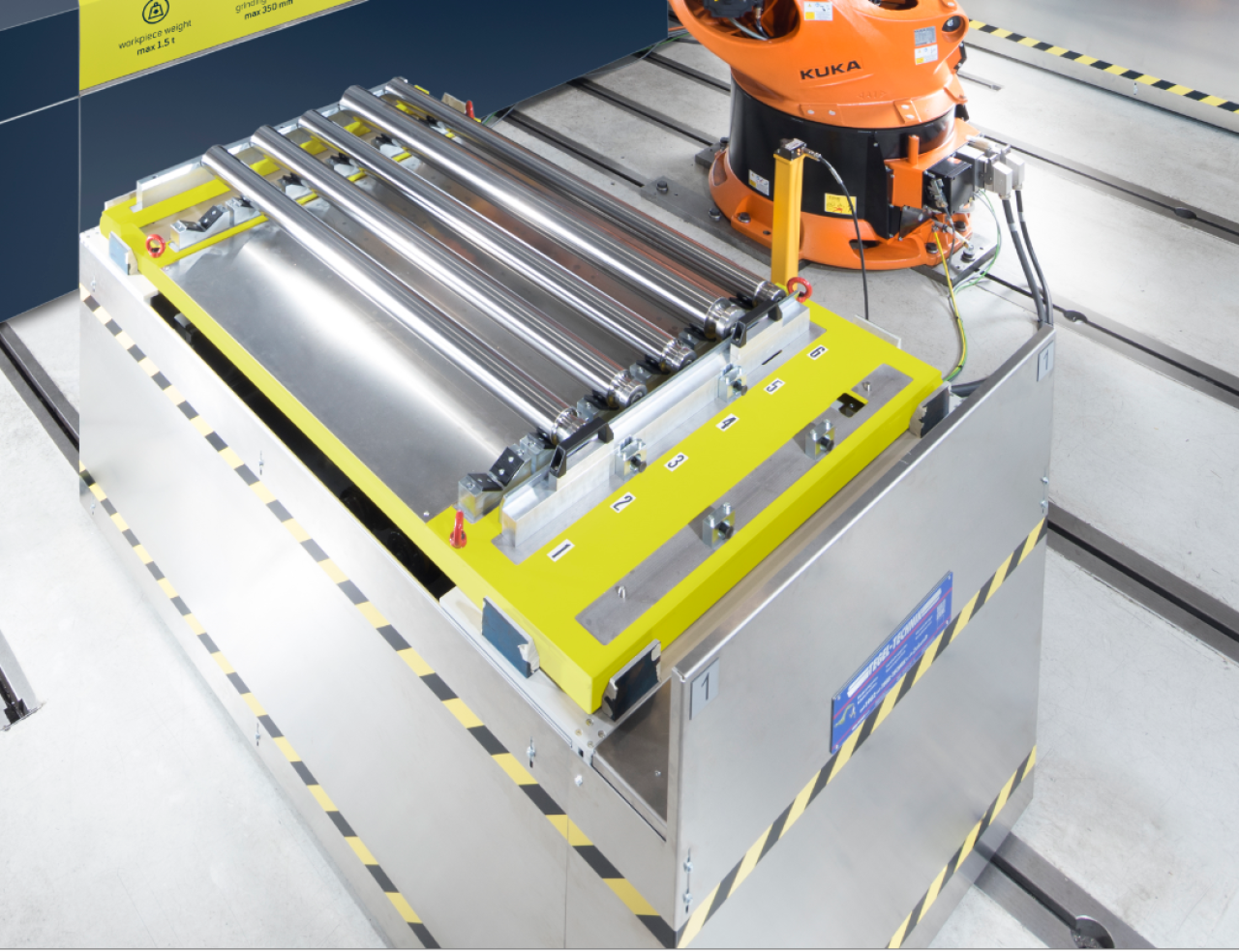

| Conveyed goods | Special racks (forklift or crane loading possible) |

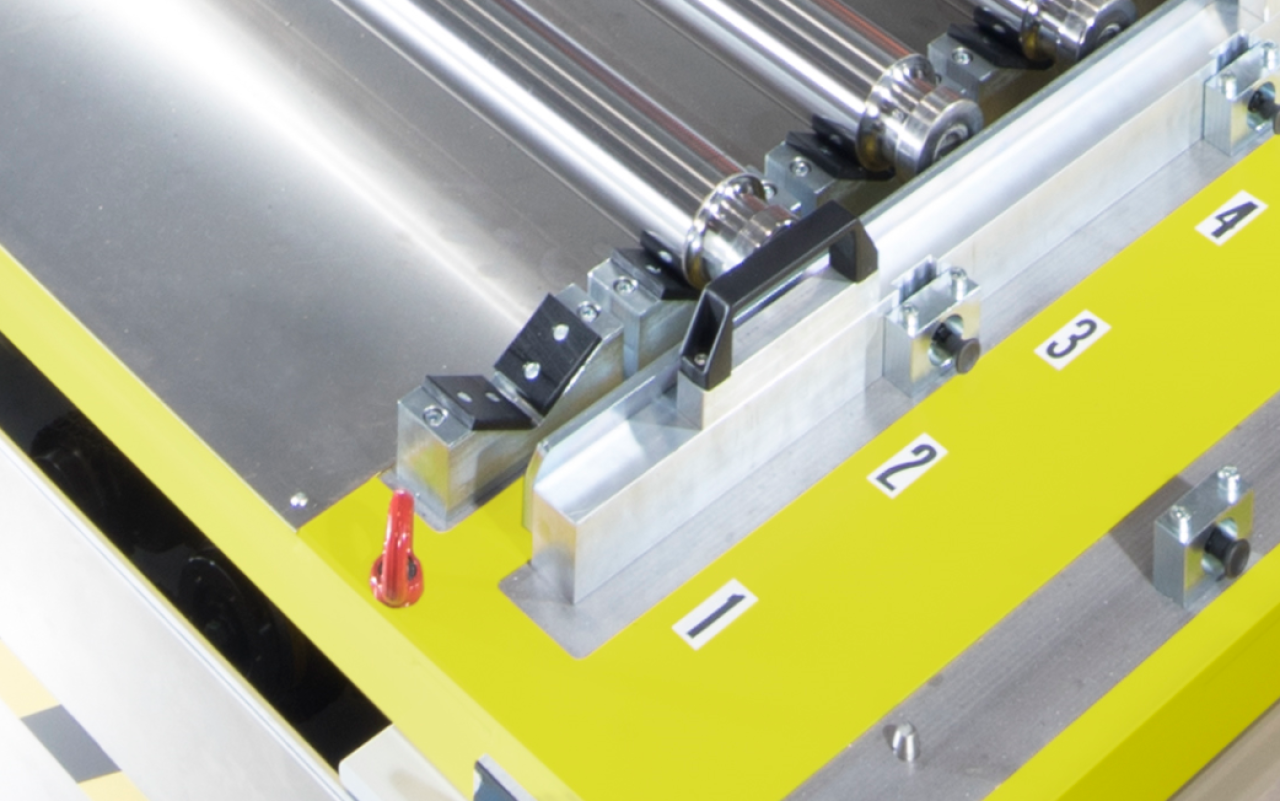

| Workpiece carriers with prism holders for the actual workpieces are located on the racks | |

| Maße der Rohre | SZ1 Ø 78 to 108mm with length 1,760mm |

| SZ2 Ø 78 bis 108mm with length 1.532mm | |

| Weight/tube | SZ1 max. 130kg, SZ2 max. 112kg |

| Conveying direction | lengthwise |

| Installation site | Dry operation in closed rooms |

| Ambient temperature | 15 °C – 40°C |

| Special environmental influences | none |

Automatic feeding of round materials to the sanding machine via telescopic rail system in robot cell

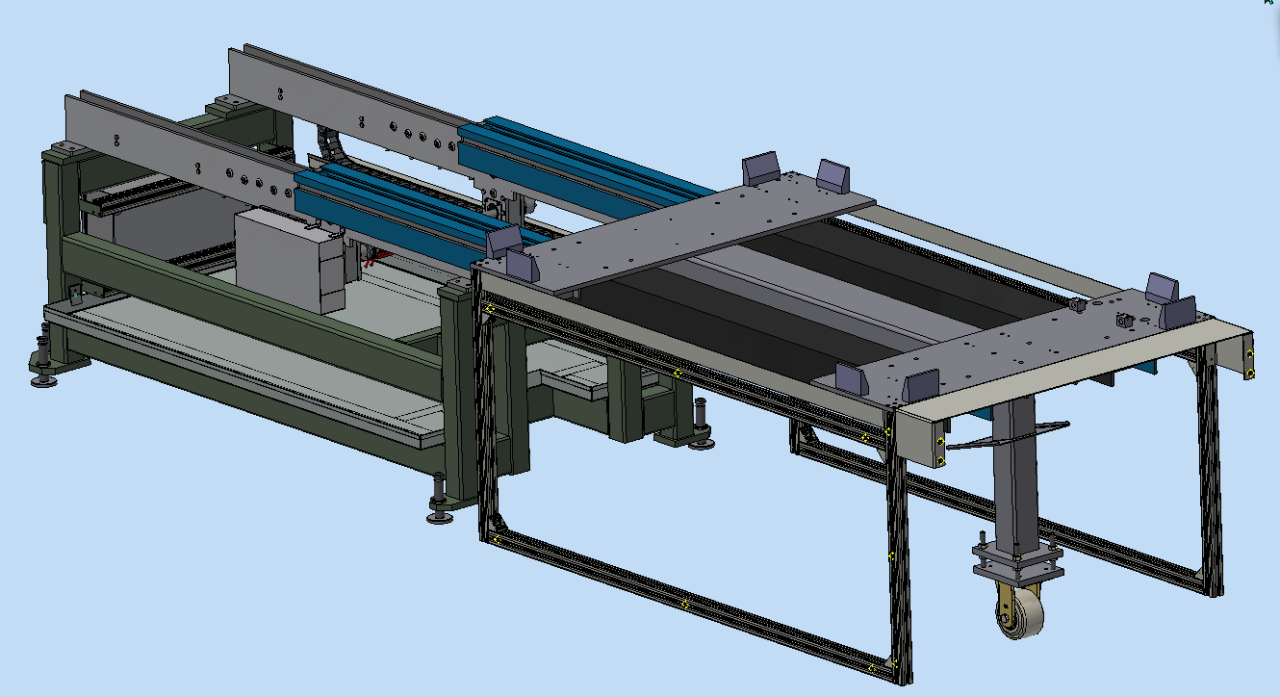

A special construction was made here consisting of a base frame, a telescopic fork with steel frame and prism mounts.

The telescopic fork is mounted on a sturdy steel base frame that is dowelled to the floor. A sturdy steel frame with guide plates is located on this telescopic fork, which the operator can use to load the extended telescopic handler.

A support roller also extends to support the extended telescope.

The weight of the telescope is designed for 1.5 tonnes and has a travel of 2,350 mm.

The yellow steel frame is inserted into the telescopic holder, which has been extended from the safety fence, via the four red lifting eyes using an indoor crane and then moved back into the robot's operating area. The robot removes the round materials to be sanded one after the other and places them back in the yellow steel frame after sanding. The telescopic rail moves the processed batch out of the safety fence area and the employee removes the finished batch with the overhead crane and inserts a new one.

Components

Special design: steel base frame, telescopic fork, prism mounts and system installation.