As a cost-effective alternative to robots, handling devices help to rationalise work processes and optimise every work step during handling. Our handling devices enable the automatic and precise handling of goods that are difficult for human employees to move or hold. The devices make it easier to lift, move, position or manipulate goods and optimise material handling in production and storage environments. Our handling equipment can handle a wide range of goods or workpieces with ease, even in challenging working environments. The automation system successfully masters tasks such as handling irregularly shaped objects or moving heavy loads.

Handling devices

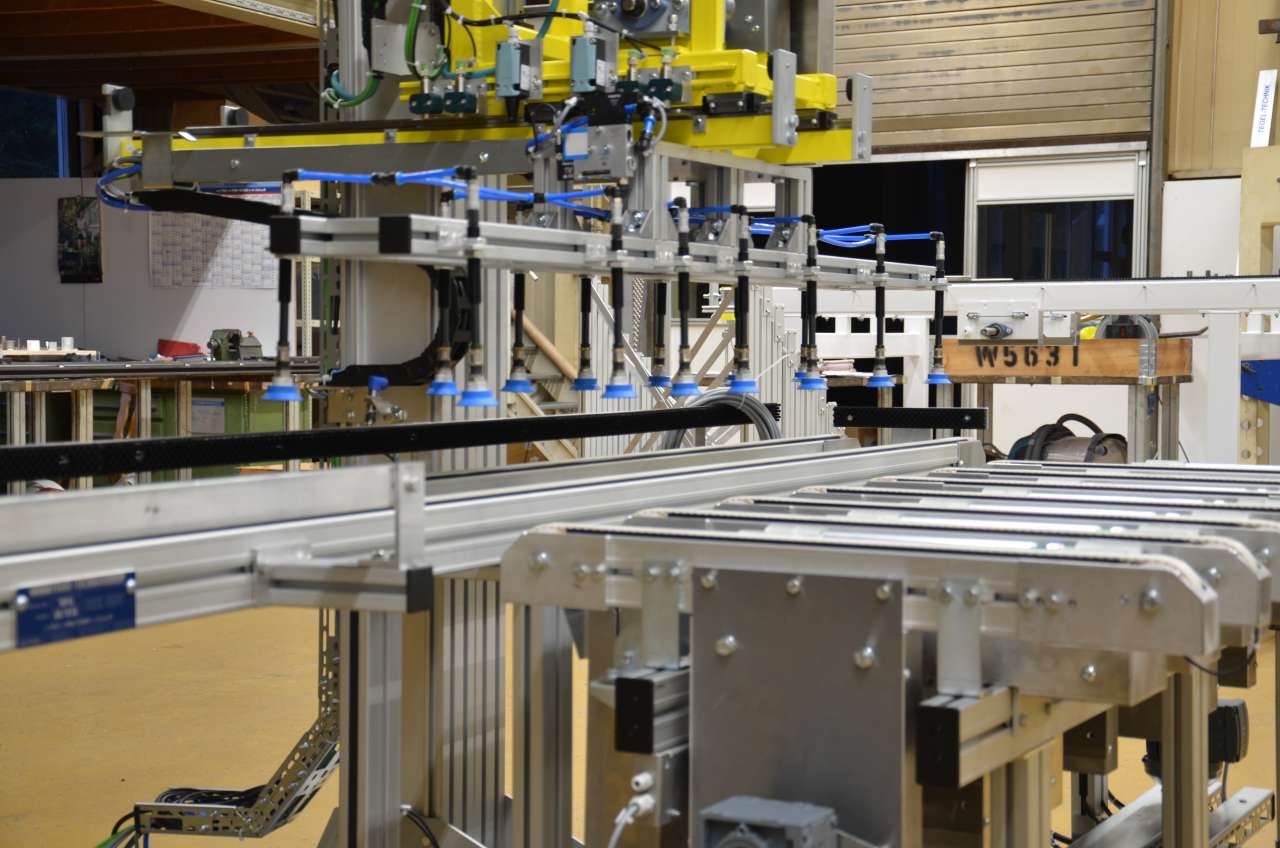

Our handling devices are available both as integrated solutions in our conveyor technology and as stand-alone solutions. Customised to your specific conveyed goods and applications, these devices can be operated both pneumatically and motor-driven.

In addition to our handling systems, we offer a wide range of different conveyor technology components. These include, among others roller conveyors, chain conveyors and pallet conveyor technology. You can find a selection of our realised projects here.

Advantages of handling equipment from TEGEL-TECHNIK

Broad range of applications: Our handling systems are used in various industries and can be utilised for a wide range of tasks. These include the quick and easy moving, turning, assembly or alignment of products such as workpieces.

Individuality and flexibility: We customise our handling technology precisely to the specific requirements of your company and the characteristics of your conveyed goods. This ensures customised integration of the handling systems into your existing working environment and system.

Robust and reliable: Our production includes robust components made from high-quality materials, specially developed for challenging working environments and heavy workpieces. This guarantees reliable operation and minimises downtime.

Efficiency and economy: Our handling technology helps to lift heavy loads and automate complex handling tasks. As a result, the handling systems support more efficient and safer material movement as well as an optimised material flow in production and warehouse environments and reduce the workload of your employees.

Everything from a single source: We offer a high level of vertical integration with an extensive range of mechanical, electrical and software services. As a company in the field of conveyor technology, we have been drawing on our valuable experience since 1982.

Design and functionality of handling systems

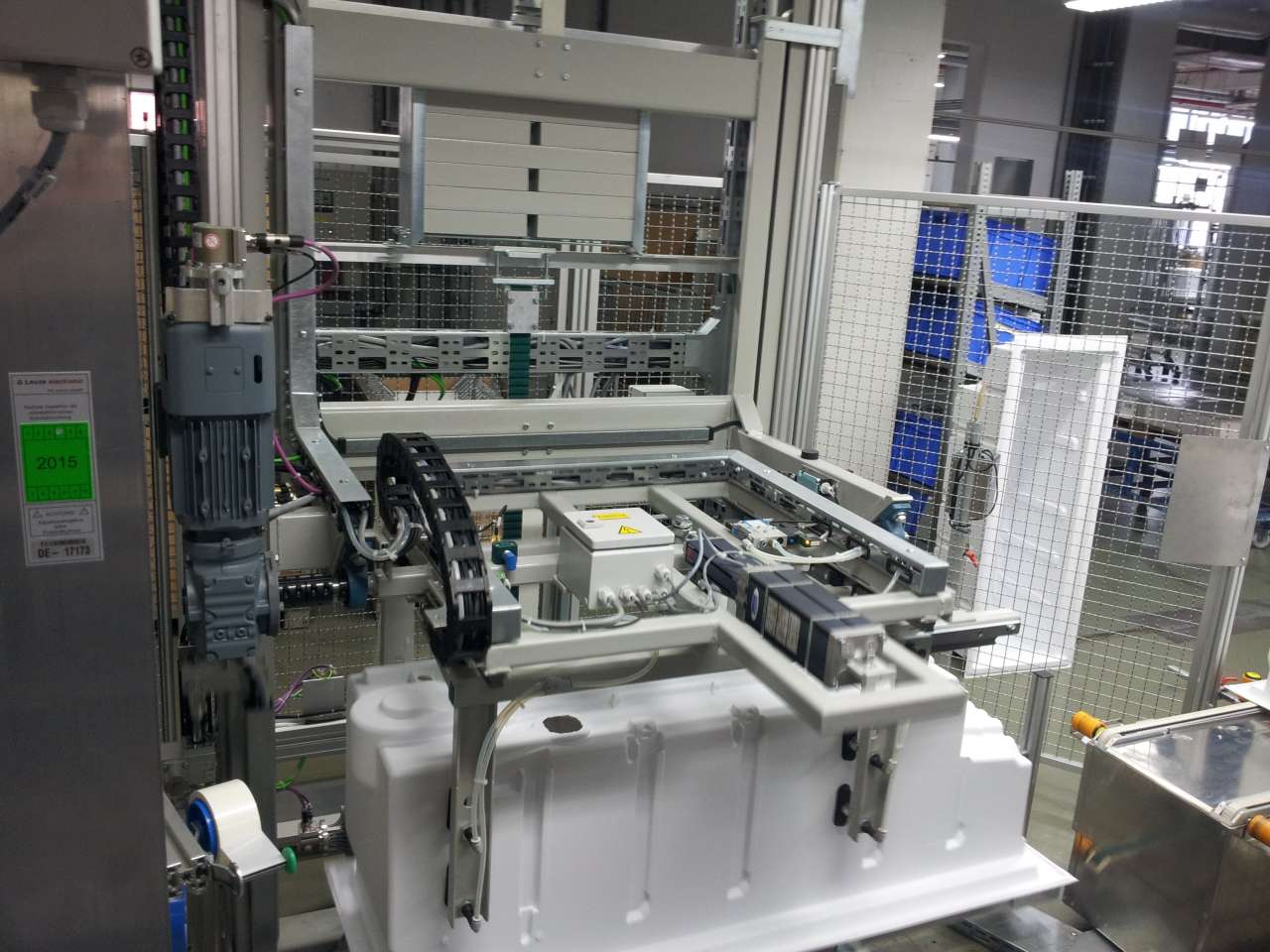

The design of handling devices in conveyor technology varies depending on the specific application and the requirements of the conveyed goods. In general, handling systems consist of stable and precise mechanical elements such as frames, levers and grippers, electric or pneumatic axes and the corresponding control components of the handling device.

Handling equipment is generally characterised by a robust structure, which can be designed as a swivel arm, gantry or in another form depending on the area of application. This structure enables precise movement and positioning of the material to be conveyed. Depending on the type of material to be conveyed, grippers or vacuum suction cups are integrated to enable safe handling. The drive type of the handling devices can be either pneumatic or motorised, depending on the specific requirements of your application. An intelligent control unit regulates the movements of the device.

To ensure safe operation, handling systems can be equipped with various safety mechanisms. These include emergency stop switches, safety sensors, light grids, safety mats and fixed guards.

Handling devices and handling equipment in use

Our handling devices are versatile and can be used in a wide range of industries and applications. From turning devices and swivelling devices to pick-up and positioning devices for the semi-automated assembly of components, they offer flexible solutions for a wide range of tasks. Automatic tilting stations enable boxes to be emptied, while suction cup or gripper modules can pick up components and place them on pallets or assembly devices via 2- or 3-axis gantries.

Gallery of our application examples

Enquire now for a customised conveyor solution

Have we aroused your interest?

Phone

+49 7322 9611–0