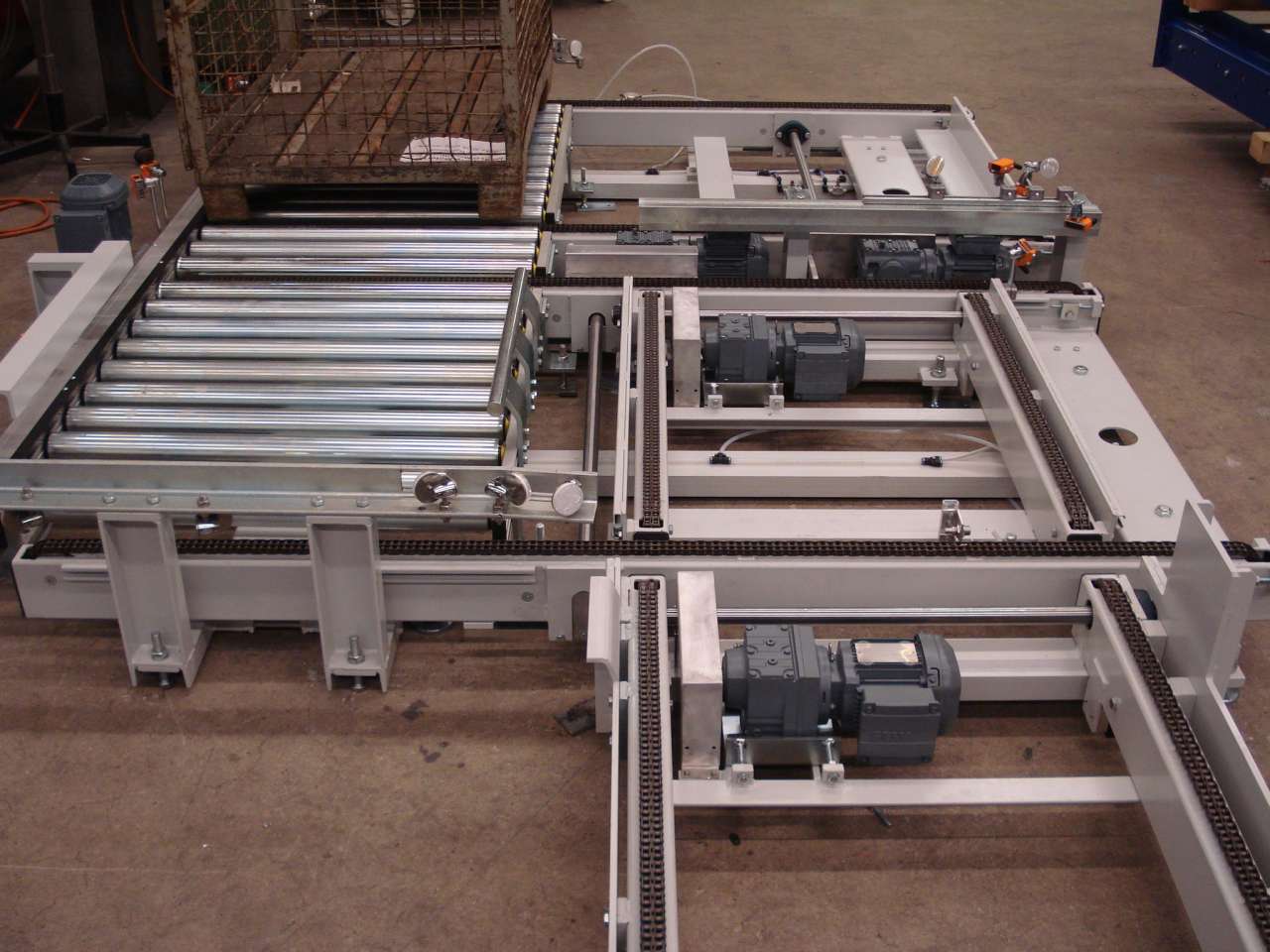

Driven roller conveyors are extremely common in the world of conveyor technology and are used to transport, feed or temporarily store goods of different dimensions and weights. They are driven by a geared motor. With a roller conveyor, it is possible to efficiently transport a wide range of goods of different sizes and characteristics. This applies both to goods with a flat surface and those with a surrounding frame. Roller conveyors with drive are versatile and are equally suitable for transporting light and heavy loads, i.e. as heavy-duty roller conveyors for pallets, workpiece carriers, boxes, crates and components. In pallet conveyor technology, roller conveyors can be considered a standard conveyor system.

Driven roller conveyors

In addition to powered roller conveyors, TEGEL-TECHNIK offers other conveyor systems with and without rollers for a wide range of applications. The powered variants are divided into roller conveyors with 400 V drive, sectional roller conveyors with 24/48 V motorised roller for zero pressure accumulation transport, accumulation roller conveyors with friction rollers and roller curves. For the non-driven variants, we differentiate between empty roller conveyors on which the transported goods are pushed on manually and inclined gravity roller conveyors on which the transported goods move on independently due to the incline or slope without being driven. You can find a selection of our realised projects here.

Advantages of roller conveyors with drive from TEGEL-TECHNIK

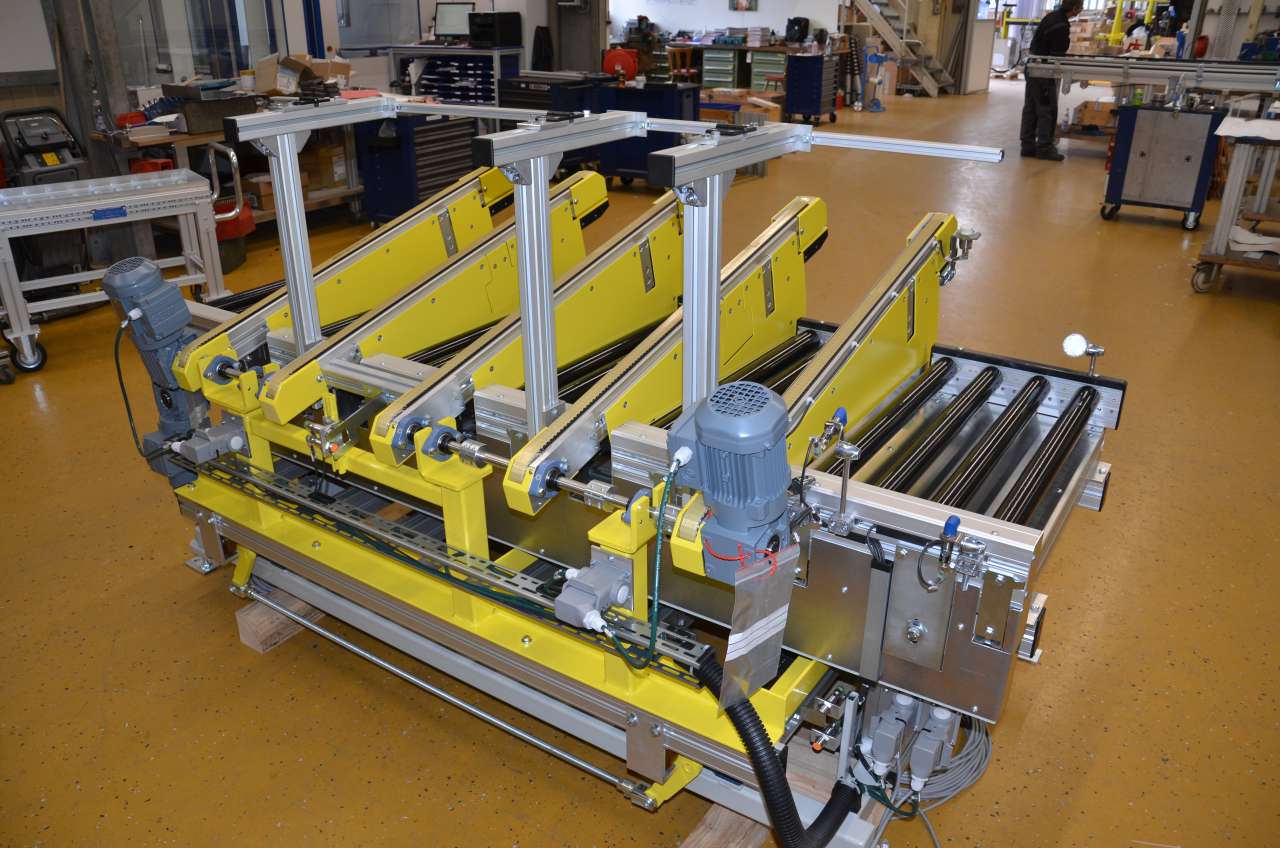

Wide range of applications: Our powered roller conveyors are extremely adaptable and can be used in various industries and applications. From logistics and storage to production and processing, our powered conveyors offer the ideal solution for every width and length.

Individuality and flexibility: The design of our roller conveyors varies depending on the transported goods. The roller diameter can vary from 20 mm for very small conveyed goods to 140 mm for extremely heavy conveyed goods. The wall thickness of the rollers and their length are also tailored to the individual application.

Robust and reliable: Our components are characterised by high-quality materials and careful workmanship. We supply robust and durable designs that are customised for reliable conveying under a wide range of conditions. In this way, we ensure long-lasting operation of the entire conveyor line for our customers.

Efficiency and economy: Our powered roller conveyors enable efficient and continuous transport of goods. The individually configured solution is able to move large quantities of materials or products with minimal manual intervention.

Everything from a single source: We offer a high level of vertical integration with an extensive range of mechanical, electrical and software services. As a company in the field of conveyor technology, we have been drawing on our valuable experience since 1982.

Design and functionality of the powered roller conveyor

Unlike passive roller conveyors, where the rollers only serve to facilitate movement, driven roller conveyors are equipped with electric drives. The motors set the rollers in motion directly or via a transmission medium (chain or belt). The speed and direction of the rollers can be precisely controlled via the control unit integrated into the system or an existing external control unit.

Depending on the type of material to be conveyed, we will make the right selection for you and your requirements for a roller conveyor. This can include, for example, the use of coated idlers for sensitive goods. Our motorised roller conveyors are available in various operating modes. Conveying can take place in a continuous mode, in cycle mode or in reverse mode, depending on what best meets your requirements for the machine. The available space between the rollers of the conveyor system provides sufficient room for the integration of stoppers and fusing units. In work areas or at processing stations, these areas of the conveyor line are often driven in segments.

Driven roller conveyors in use

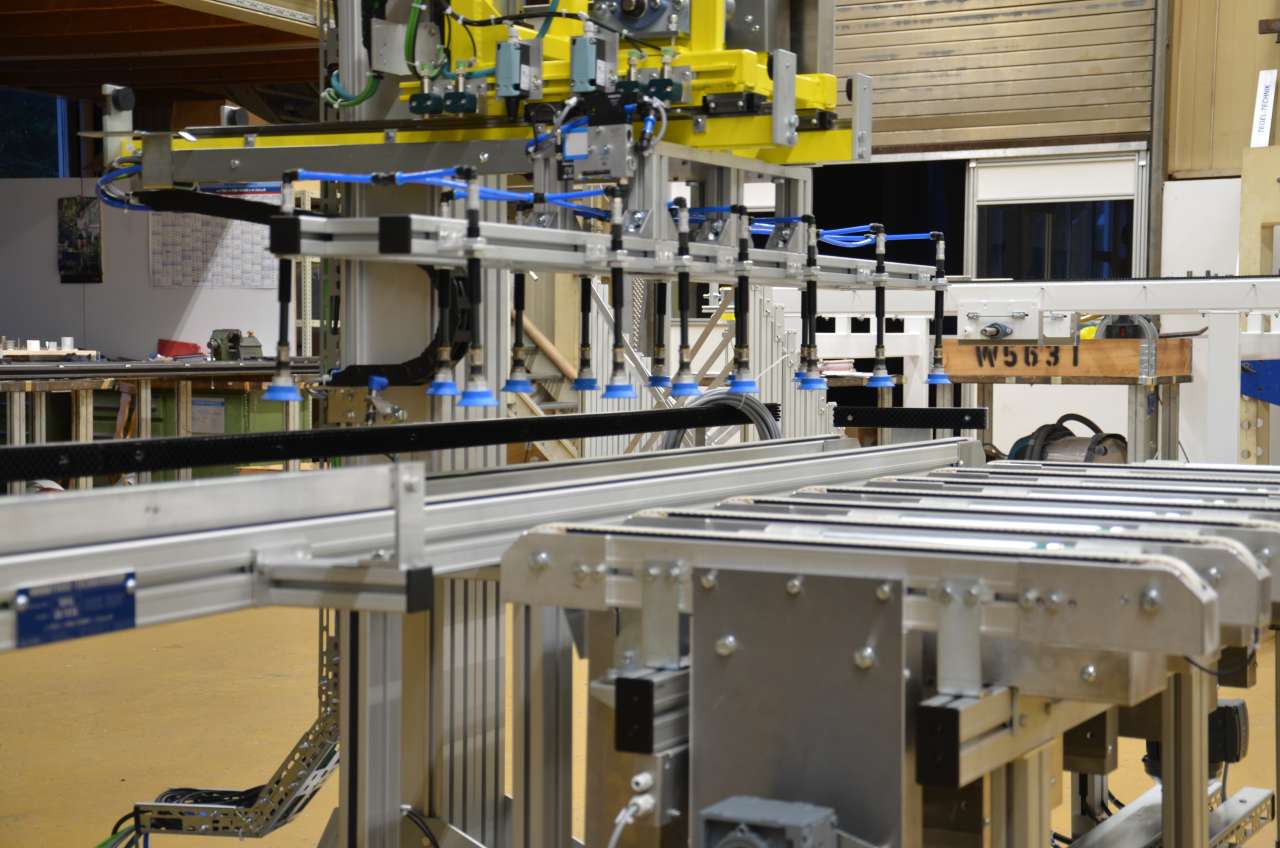

We have implemented driven roller conveyors for testing and evacuating cooling units for our customers. The refrigerators are fed into an evacuation circuit from the final assembly line using a roller conveyor. The refrigerators are transported over the driven roller conveyors using workpiece carriers and then lifted off the workpiece carriers again.

For transporting plastic crates over several levels, we also use straight roller conveyors and curved roller conveyors with drive, in combination with conveyor belts, rotating units and stoppers. In this driven application, two full crates are simultaneously removed from the upper level and two empty KLTs are fed into the lower level. After delivery, the empty KLTs are orientated in the same direction via a small turntable. The containers then travel to the higher level via a powered conveyor belt and are filled at various stations. In the final step, the containers are transported to their removal position, where the removal-loading cycle starts all over again.

Gallery of our application examples

Have we aroused your interest?

Enquire now for a customised conveyor solution

Phone

+49 7322 9611–0