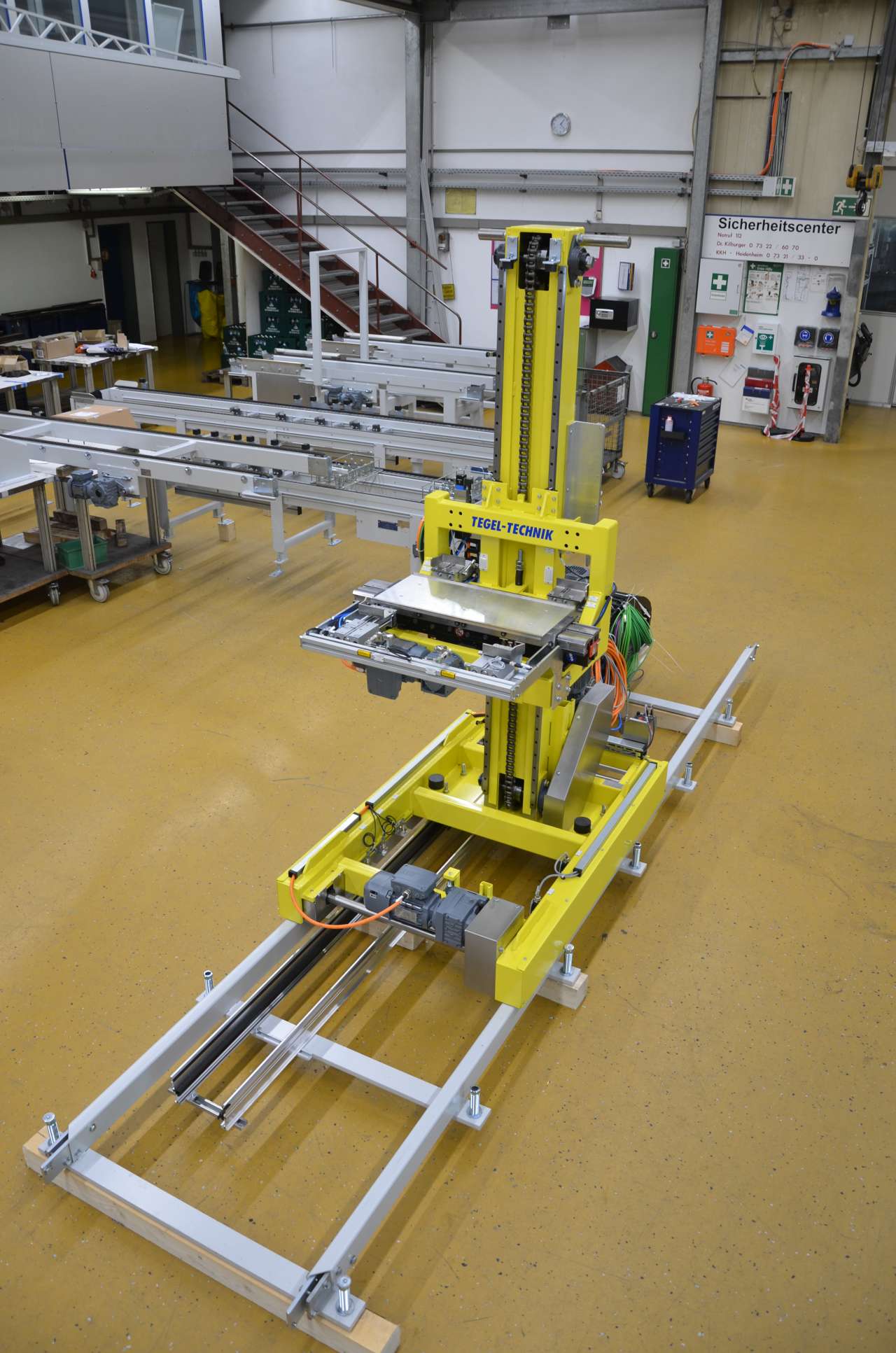

Transport trolleys, also known as transfer trolleys or transfer carriages, offer an optimum solution for connecting a feed station with several dispensing stations and vice versa. Essentially, these are vehicles that are mounted on rail systems and can be supplemented with different superstructures. By integrating a vertical axis, the transport trolley becomes a storage and retrieval unit, which enables goods to be stored and retrieved perfectly at different levels.

Travelling carriage

Travelling carriages are particularly effective when it comes to distributing transported goods on parallel conveyor lines, e.g. with chain conveyors, with the same or different heights. They can also be used to quickly and easily connect distant conveyor sections, e.g. in production. They are ideally suited as load handling devices for the simple distribution and linking of conveyed goods in different areas of application, whether in order picking and buffer areas or in conjunction with racking systems in logistics.

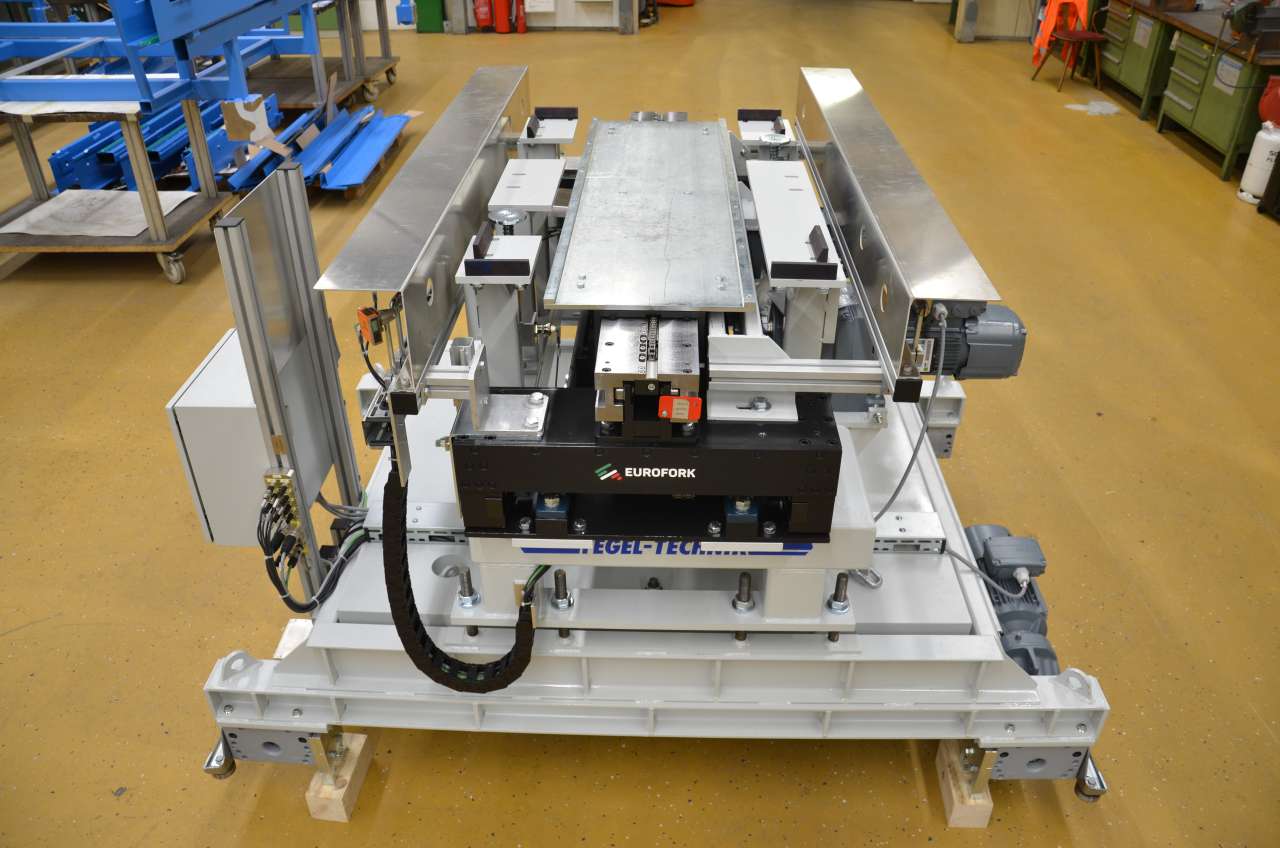

Different superstructures for a traversing system include familiar conveyor elements such as roller conveyors, chain conveyors, belt conveyors and toothed belt conveyors are used. For special applications, components such as telescopic forks or other special designs can also be installed. All superstructures can be supplemented with rotary tables, stroke transfer units or vertical axes. You can find a selection of our realised projects here.

Advantages of travelling carriages in TEGEL-TECHNIK

Broad range of applications: Our systems with transfer carriages are versatile and can be used in various applications such as order picking, buffering, distribution or for the general transport of goods in production or intralogistics.

Individuality and flexibility: Thanks to their high adaptability, our transfer carriages can be easily integrated into different conveyor lines and for demanding requirements. It doesn't matter whether the conveyor lines have different positions or heights. The flexibility also extends to customised integration into automated conveyor systems in order to optimise the material flow.

Robust and reliable: The robust design of our transfer carriages ensures a very high level of reliability in industrial use. The transfer carriages are designed to provide a stable and durable solution for the smooth transport of goods in various working environments, such as warehouse systems.

Efficiency and economy: Thanks to their precise control, our transfer carriages make a significant contribution to optimising the flow of materials in industrial processes. This leads to increased productivity and profitable workflows. At the same time, our flexibly deployable transfer cars enable a resource-saving and cost-effective solution for in-house goods transport.

Everything from a single source: We offer a high level of vertical integration with an extensive range of mechanical, electrical and software services. As a company in the field of conveyor technology, we have been drawing on our valuable experience since 1982.

Design and functionality of traversing systems

The base frame of transfer carriages is the chassis. This consists of a sturdy steel frame to ensure a robust structure. The technical drive system is crucial for the mobility of the transport trolley. The drive is realised by a frequency converter-controlled electric motor or servomotors in order to achieve high dynamics and positioning accuracy. The trolley is driven directly at the wheel axles or via an intermediate, maintenance-free toothed belt.

The control unit is the centrepiece of the transfer car. It controls the movement of the superstructures and the positioning of the trolley in relation to the interfaces. The conveyor system on the transport trolley can have different variants, including roller conveyors, conveyor belts or other special devices tailored to the type of goods to be transported. Depending on the type of goods being transported, special devices such as brackets, pallets or other holding mechanisms can be attached to the trolley to hold the goods securely in place. One example is the transport of pallet cages with contents.

The trolley retains its tracking stability even at high speeds. This is ensured by laterally mounted guide rollers that guide the wheels on the rails. The long-lasting and low-wear Vulkollan wheels ensure smooth running thanks to the cushioning properties of the tyre. Depending on the application, power can be supplied either by a conductor rail or a drag chain.

To ensure safety when working with traversing systems, the traversing area is usually equipped with a safety fence. In addition, various safety devices such as emergency stop switches, obstacle detection sensors or other warning devices can be used.

Conveyor technology with transport trolleys in use

Our transport trolleys are used in a wide range of applications and impress with their flexibility and precision. In order picking, they ensure the smooth transport of goods, while in buffer areas they enable the efficient distribution of goods to the various buffer sections. The transport of goods between different workstations and conveyor lines is optimised by the individual adaptability of the transfer carriages. Their use in automated conveyor systems also helps to increase overall efficiency and productivity.

We have realised various projects for our customers. These include distribution trolleys for Euro pallets, storage and retrieval machines for special pallets, transfer carts for conveyor technology with integrated turning station, the distribution of refrigerators or the transport of hardening batches.

Gallery of our application examples

Have we aroused your interest?

Enquire now for a customised conveyor solution

Phone

+49 7322 9611–0