Curved conveyors play a crucial role in conveyor technology as they enable the seamless transport of goods in production facilities and warehouses in different directions. The purpose-built conveyors transport goods and materials in curved or angled sections and can be installed at different radii and angles to meet specific space requirements. A curved conveyor enables the transport of a variety of goods regardless of their size, width or length - whether with a flat surface or a circumferential frame. The specialised conveyors handle the transport of both lighter goods and heavy loads, such as pallets, workpiece carriers, boxes, crates and much more. Curved conveyors therefore offer a versatile solution for different transport requirements in various industries and applications.

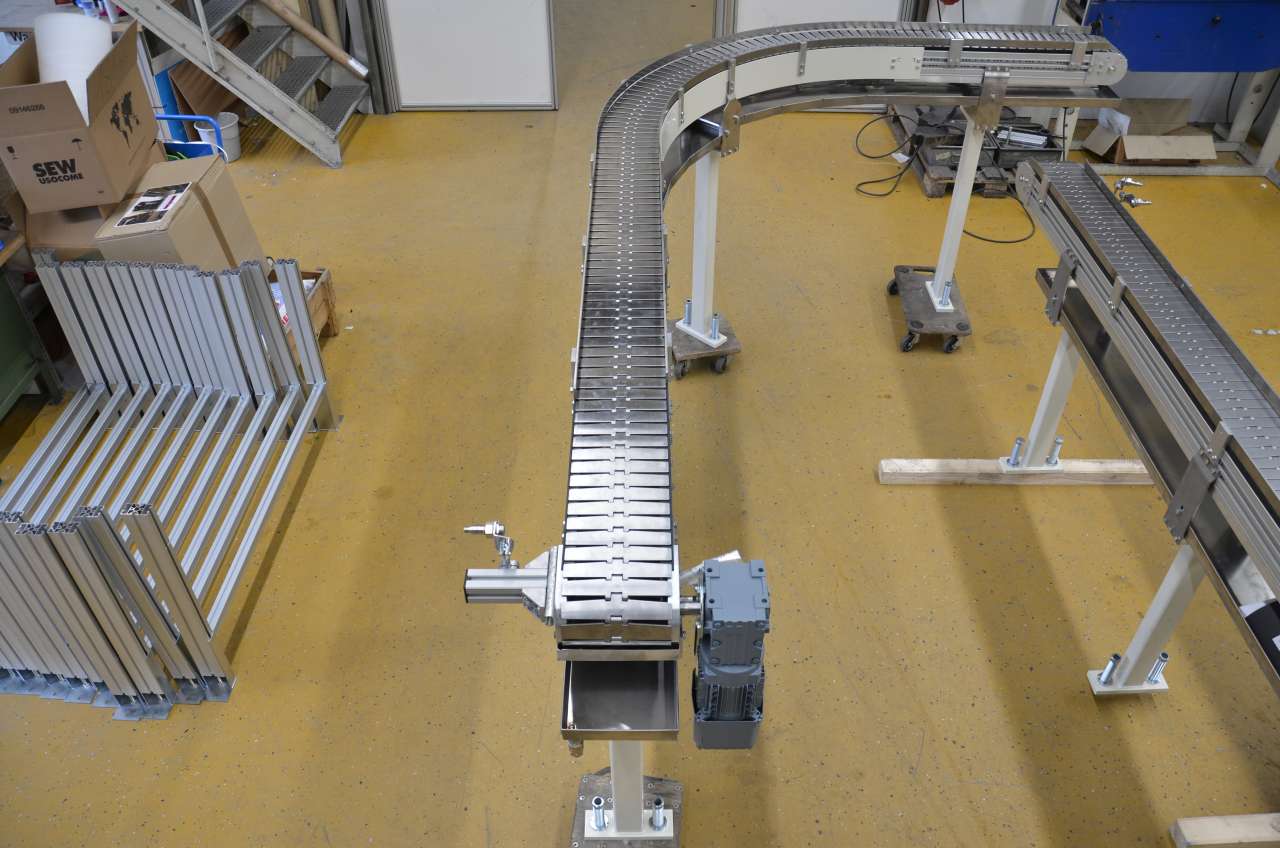

Curved conveyor

Similar to roller conveyors, curve conveyors are available in two versions: the non-driven and the driven version. In the driven version, they offer a wide range of transport options as roller curves, belt curves and modular belt curves. You can find a selection of our realised projects here.

Advantages of curve conveyors from TEGEL-TECHNIK

Broad range of applications: Our curve conveyors enable seamless transport of goods between different work stations. They are always used when straight line operation is not sufficient.

Individuality and flexibility: Our curve conveyors are extremely adaptable and can be built at different angles and radii as required to meet the spatial requirements of a plant or production process.

Rugged and reliable: Our curve conveyors are characterised by a stable design, a long service life and minimal maintenance. This ensures low operating costs and long-term profitability.

Efficiency and economy: Our curve conveyors are an economical solution for flexible material transport and help to make your production processes efficient and cost-effective.

Everything from a single source: We offer a high level of vertical integration with an extensive range of mechanical, electrical and software services. As a company in the field of conveyor technology, we have been drawing on our valuable experience since 1982.

Design and functionality of curve conveyors

Curved conveyors can consist of rollers, curved plate or link belts, or curved belt conveyors. In the case of rollers, the conveyed goods move through the curve in a rolling motion. In all other designs, the conveyed goods rest on the transport medium and are carried through the curve. The curve modules enable controlled guidance of the conveyed goods at the desired angle. They are designed to enable the continuous transport of various goods. This is particularly useful in applications where a uniform material feed is important.

The curve conveyor takes the incoming goods and returns them to the outgoing conveyor in the identical orientation. With a conveyor curve, for example, 45°, 90°, 180° and almost any other number of degrees can be realised.

Curved conveyors in chain or belt design are always driven. Roller curves differ between driven and non-driven versions. In the non-driven version, the conveyed goods are transported, for example, by gravity over a gradient or using muscle power. They are used where conveyed goods such as packages or boxes still have to be picked up or pallets or workpiece carriers that still have to be moved manually.

Curved conveyor in use

Curved conveyors are used in a wide range of industries and applications. In the automotive industry, roller conveyors with curves enable the smooth transport of vehicle parts from one production station to the next. Conveyor systems with roller conveyors and curves are also used in warehouses and distribution centres to sort and move goods efficiently.

For the transport of plastic crates over several levels, we also use straight and curved roller conveyors with drive, in combination with conveyor belts, rotating units and stoppers. In this application, two full crates are simultaneously removed from the upper level and two empty KLTs are fed into the lower level. After delivery, the empty KLTs are orientated in the same direction via a small turntable. The containers then travel to the higher level via a conveyor belt and are filled at various stations. In the final step, the containers are transported to their removal position, where the removal-loading cycle starts all over again.

Gallery of our application examples

Have we aroused your interest?

Enquire now for a customised conveyor solution

Phone

+49 7322 9611–0